Evaporative Cooling Technologies: Off-Grid Refrigeration for Developing Countries

- sarahnoorjamani

- Oct 29, 2023

- 6 min read

Updated: Oct 30, 2023

Experimental Study of Alternatives to Sand in Zeer Pot Refrigeration Technique

Table of Contents:

Purpose

The purpose of this experiment is to test the effectiveness of charcoal and gunny sack as alternatives to sand in zeer pot evaporative coolers and to test the performance of different zeer pot covers (fully covered wet cloth, partially covered wet cloth, no cover, clay cover).

QUESTIONS:

Which filler material (sand, charcoal or gunny sack) when used as an absorbent material will have the better evaporative cooling efficiency ? What drop in inner pot temperature (◦C) will this correspond to?

What is the maximum variation between the ambient air temperature (Ta) and temperature inside the zeer pot (Ti) as it relates to evaporative cooling efficiency?

How does the difference between the wet bulb temperature and ambient temperature (Ta - Tw) affect the evaporative cooling efficiency?

Do different zeer pot covers (no cover, full wet cloth or partial wet cloth cover) produce different cooling efficiencies?

OVERALL QUESTION:

What are the key factors affecting the performance of the zeer pot evaporative coolers?

Affordable and Scalable: Evaporative Cooling CAN Fight Food Loss

Evaporative cooling devices have the promise of helping small-scale farmers, market vendors and families to store and preserve vegetables. The Zeer pot is a practical and affordable storage technology that has the potential to prevent food loss, strengthen the perishable food supply chain, and create opportunities for additional income generation. Evaporative cooling devices are simple and inexpensive ways to keep vegetables fresh without the use of electricity.

The World Bank National Survey (2019) highlights how far Africa is lagging compared to the world and the variation within the continent. It has a current 43 percent average access rate to electricity which is half of the global access rate of 87 percent. The Zeer pots is based on the principle of “evaporative cooling”, where the evaporation of water from the surface removes heat, creating a cooling effect.

Background Research - What Is a Zeer Pot? A Natural and Chilly Solution to World Hunger

Evaporative cooling can improve vegetable storage shelf life by providing a stable storage environment with low temperature and high humidity, which reduces the rate of respiration and water loss and spoilage in most vegetables. The improved storage environment can have positive impacts including reduced post-harvest losses, less time spent traveling to the market, monetary savings, and improved nutrition.

What Is Evaporative Cooling? How Does it Work?

How Efficient is Each Experimental Zeer Pot?

η = Cooling Efficiency (%)

Cooling Efficiency (%) is the percentage of maximum temperature drop achieved by the device. A hundred percent indicates that the temperature inside the evaporative cooling device has dropped to the wet-bulb temperature.

The wet bulb temperature (ºC) measures air temperature at 100% relative humidity and marks the lowest temperature attainable via evaporative cooling. The wet bulb temperature (Tw) is calculated using the following equation:

Importance of Ethelene (Fruit Ripening Hormone) and Post Harvest Loss

Ethylene is a gaseous plant hormone that triggers the ripening process for many fruits like tomatoes. The fruit ripening process occurs in the later stages of growth and development. Fruit ripening results in changes in fruit quality characteristics. The color of the fruit typically darkens, the skin and flesh soften, and the green background color fades.

An unripe fruit generally has low levels of ethylene. As the fruit matures, ethylene is produced as a signal to induce fruit ripening. Ethylene production continues to increase after harvest, thus decreasing fruit shelf-life, storability capacity, and increasing its susceptibility to pathogen attacks. Monitoring and managing ethylene production rates is of crucial importance so fruit does not become over-ripe on the tree or during postharvest storage.

In this experiment the amount of ethylene before and after will not be measured but a general qualitative observation of tomato quality will be recorded. A scale from 1 - 10 was developed.

Pot-in-Pot Evaporative Cooler - Why Clay?

PERMEABILITY…

Clay pot coolers have been used for centuries to help farmers reduce food spoilage and waste, increase their income, and limit the health hazards of spoiled foods.

The pot-in-pot design, commonly known as a “Zeer pot,” was popularized in 1995 by Mohammed Bah Abba in Nigeria and is composed of two clay pots with the same shape but different sizes.

Evaporation occurs through the outer clay pot. The permeability of this layer plays a significant role in determining the actual rate at which water is evaporated. Earthenware is the type of clay that is used to construct zeer pots.

This type of clay is relatively porous and permeable in relation to other forms of clay. In addition to permeating through the outer clay pot, water must travel through the sand to continuously replace moisture that has passed through the clay and evaporated.

The cooling effect will be limited both by this diffusion rate and the permeability of the clay.

Physical Properties of Insulating Materials (Sand, Charcoal, Gunny Sack)

Foundation for Experimental Design

Prototype Experiments

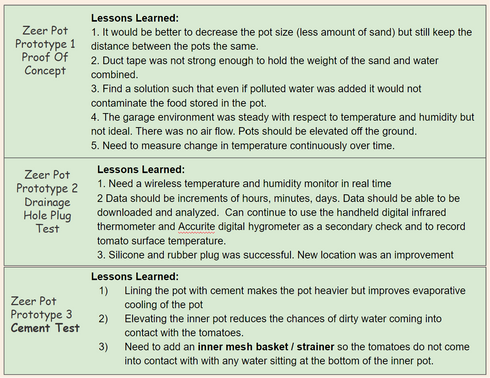

I followed the Engineering Method and created three different prototypes (P1, P2 and P3) to test different aspects of the zeer pot construction and defining variables. Lessons learned from the prototype phase were incorporated into the final experimental design and test.

LESSONS LEARNED:

The inner clay pot was covered with a thin layer of cement. This will prevent water from diffusing through the pores. This will allow families to use polluted / non-potable water. This is advantageous in villages where access to clean water is scarce. The clay pot should still be kept clean. The cement is another method of hygiene that can be easily implemented in the field.

Hypothesis and Variables

Hypothesis:

If I test different types of insulating materials (sand, charcoal, gunny sack) and zeer pot covers (no cover, fully covered wet cloth, partially covered wet cloth, and clay cover) then the evaporative cooling efficiency (η) will be greatest with gunny sack and partial wet cloth. because this design combination will have the greatest evaporative cooling potential.

Independent Variables: (tested separately)

1. Zeer Pot Cover (No Cover, Wet Cloth Fully Covered, Wet Cloth Partially Covered, Clay Cover)

2. Zeer Pot Filler / Insulating Material (Sand, Charcoal, Gunny Sack)

Dependent Variables:

1. Temperature (℃) - Inner pot temperature (Ti), Ambient temperature (Ta), Wet Bulb Temperature (Tw)

2. Relative ambient humidity RH (%)

3. Tomato ripeness and quality (color indicator for ethylene, mold, appearance)

Control: Tomato left outside in its natural environment (no pot, no filler material, no water)

Constants: Inner/Outer Pot Size, Pot Material (Terracotta), Pot Feet, Rubber Stopper/Silicone, Cement, Variety and Source of Tomatoes (Farm), Instruments (Wireless Hygrometer, Digital Thermometer, Temperature Gun), Pot Location (Covered Patio), Water Source (Tap), Ruler, Notebook, Camera, Hygrometer Data Collection App

Materials List

Engineering Experiment Sampling Plan Acronyms

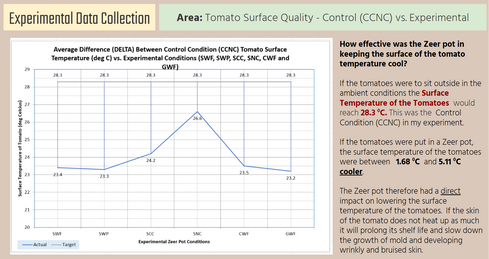

There are 6 experimental Zeer pots (SWF, SWP, SCC, SNC, CWF, GWF) and one experimental control sampling plan (CCNC). The purpose of the control is to answer: How long it would take the tomatoes to perish if they were sitting out without any refrigeration.

Procedure

Experimental Data Collection

Data Analysis - RESULTS

Conclusion and Further Research

My hypothesis was partially correct. I tested different types of insulating materials (sand, charcoal, gunny sack) and zeer pot covers (no cover, fully covered wet cloth and partially covered wet cloth) and found the evaporative cooling efficiency (η) was greatest with sand. My hypothesis predicted gunny sack. This performed second best. My hypothesis was correct in predicting that the partial wet cloth would be the most effective. This design combination will have the greatest evaporative cooling potential. This study shows how a simple low tech solution can reduce post-harvest losses, less time spent traveling to the market, and improved overall nutrition.

What Next … Irrigation with Buried Clay Pots

While completing this project, I have became interested in technologies that specifically target low-income off-grid populations. I hope to volunteer with an NGO working one day in the Sahel region of West Africa that includes Mali, Niger, Burkina Faso, and Northern Nigeria, as well as East Africa and India.

In dry and arid regions where evaporative cooling devices are most suitable, climate change is expected to result in more frequent droughts and floods. This project can be extended to irrigation with buried clay pots. This uses the same evaporative cooling principle while targeting the water where it is needed. Evaporative cooling devices have great promise in fighting hunger and empowering local farmers.